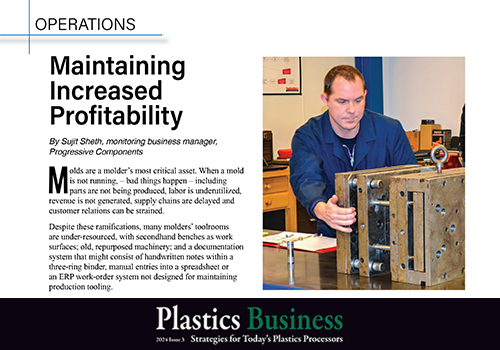

Molds are a molder’s most critical asset. When a mold is not running, – bad things happen – including parts are not being produced, labor is underutilized, revenue is not generated, supply chains are delayed and customer relations can be strained.

Despite these ramifications, many molders’ toolrooms are under-resourced, with secondhand benches as work surfaces; old, repurposed machinery; and a documentation system that might consist of handwritten notes within a three-ring binder, manual entries into a spreadsheet or an ERP work-order system not designed for maintaining production tooling…

» Click HERE to read the full article.

» Click HERE to download a printable PDF.